Connectors

Amphenol has been designing and manufacturing electrical and electronic connectors since the company’s inception in 1932. For nearly a century, we’ve been helping customers transmit power, data and signal in the harshest environments, from subsea applications to the outer reaches of space and everywhere in between. Our wide array of electrical and electronic connectors come in multiple form factors and are designed to meet the latest market needs including high power, high speeds, size and weight reduction, EMI shielding, hermeticity, high pressure and improved board retention. Amphenol also offers a broad portfolio of contact styles, termination types, mating styles, connector geometries and environmentally-friendly RoHS plating.

View our businesses providing Connector solutions.

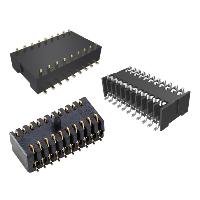

COM-HPC 0.635mm pitch 400 pin Open-Pin-Field Array

400POS 0.635MM PITCH COM-HPC

Amphenol has developed a pair of 400pos 0.635mm COM-HPC which support 5mm and 10mm stack heights.

COM-HPC is a PICMG sponsored open standard for a family of high performance computer modules targeting the embedded computer space. We have developed a pair of 400pos 0.635mm COM-HPC which support 5mm and 10mm stack heights.

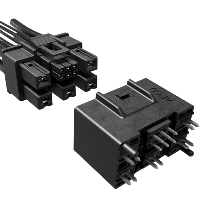

Compact Combo Connectors

SIGNAL & HYBRID SOLUTIONS FOR BTB, WTW, AND WTB

Solutions offer optimized space, high reliability with adequate creepage and clearance distances for power and allows easy to mate/crimp and cable management. The connector system offers hybrid solutions choice of signal and power loading with an active latching feature.

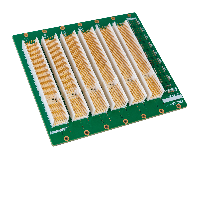

Compact PCI Serial 3U 6-Slot Backplane

Amphenol-BSI’s range of PICMG compliant backplanes includes CompactPCI Serial which modernizes CompactPCI to include high-speed serial Ethernet, PCIe, SATA and USBinterconnects. These high-speed serial interconnects are capable of data rates up to 12Gb/s.

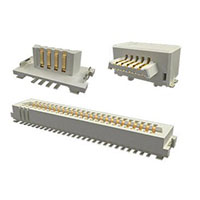

Compression Connectors

SINGLE-PIECE COMPRESSION TYPE SURFACE MOUNT CONNECTORS

Amphenol Communications Solutions offers compression-type surface mount connectors to provide power and signal connection between either two PCB modules or one PCB and an electrical module. The single-piece small footprint solution brings cost and space savings to the design of smaller and more economical consumer electronic devices.

μCom USB3.0

Miniature multi-pin USB3.0 connectors for harsh environments.

Conan® 1.00mm Connector

Amphenol's Conan® 1.00mm is a mezzanine connector designed for industrial applications and harsh environments. Conan® 1.00mm provides a mechanically secure, high-density electrical interface between parallel printed circuit boards.

Its unique design with an audible 'click' sound enhances the security and ease of use. The polarization ensures proper alignment during blind mating.

Conan® Lite 1.00mm Connector

Conan® Lite 1.00mm connectors come with a robust metal down feature that helps in establishing a reliable connection with the PCB in both parallel and perpendicular board-to-board applications. These connectors also feature an audible "click" sound ensuring mating in place. Conan® Lite vertical headers, receptacles and right angle headers are offered in 9-69 positions.

CONEC AT/DT and VSS Superseal Series

Whether tractors, excavators, or construction machines, the segment IVCM (Industrial Vehicles and Construction Machines) places high demands on the connectors used. The CONEC series of overmolded AT, DT, superseal connectors are assembled in-house and overmolded and thus provide optimal protection against external influences in harsh environments. Degree of protection: IP67/IP69K.

CONEC ATM connectors

The ATM connector series is designed as a cable-to-cable connection. It locks securely and without tools via a latch. The series is not only used in agricultural, agricultural and vehicle technology, but also frequently in process automation and control technology. The overmoulded ATM connectors are available as plugs and sockets in the variants connecting cable with open cable end or connecting cable.

CONEC CPC Connector Series

In addition to agricultural and automotive engineering, CPC connectors are frequently used in control cabinets, robotics, injection molding machines, and machine tools. This design is a robust connector which, in contrast to the previous agricultural connectors in the CONEC product range, has a threaded connection with positive detent and is smaller in size than, for example, an ISOBUS connector.