Connectors

Amphenol has been designing and manufacturing electrical and electronic connectors since the company’s inception in 1932. For nearly a century, we’ve been helping customers transmit power, data and signal in the harshest environments, from subsea applications to the outer reaches of space and everywhere in between. Our wide array of electrical and electronic connectors come in multiple form factors and are designed to meet the latest market needs including high power, high speeds, size and weight reduction, EMI shielding, hermeticity, high pressure and improved board retention. Amphenol also offers a broad portfolio of contact styles, termination types, mating styles, connector geometries and environmentally-friendly RoHS plating.

View our businesses providing Connector solutions.

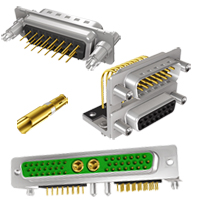

CONEC D-SUB Filter connectors

With increasing data transmission rates and operating frequencies, it is becoming increasingly important to ensure the function of electrical devices and systems in each other’s environment in order to guarantee trouble-free operation. CONEC filter connectors help to dissipate conducted interference directly at the interface. Filter D-SUB connectors are available as standard, high density or dual port.

CONEC D-SUB Series

CONEC D-SUB connectors are available in five standardized housing sizes in the variants D-SUB Standard, D-SUB High Density, D-SUB Filter, D-SUB Combination, D-SUB Filter Combination and D-SUB hoods. Depending on the mounting type and number of poles, a choice can be made between crimp, wire-wrap, solder pin, solder cup and insulation displacement terminal connection types.

CONEC Hybrid Connectors

The CONEC Hybrid connector series combines power supply and data transmission in one connector. Different sizes ( B12, B17, B23, B40 ) for various power classes from drives or devices offer maximum flexibility. Whether for small DC drives or powerful servo drives, CONEC Hybrid connectors are the perfect solutions.

• According to IEC 61076-2-118 standard

• Shorter assembly times

• Bayonet locking

CONEC IO-systems junction boxes

Our IO distribution systems offer a powerful and reliable solution for the structured distribution of input and output signals in modern automation environments. Both passive distribution systems for simple signal distribution without intelligence and active I/O boxes with integrated electronics for direct communication with controllers via fieldbus systems or Industrial Ethernet are available.

CONEC IP67 D-SUB Series

These connectors are used where dust and spray water occur and the functioning of usual connectors would be negatively affected. These connectors are available as standard, high density, filter, or combination in the usual pole number.

CONEC IP67 D-SUB SlimCon

The IP67 D-SUB CONEC SlimCon connector series offers very small dimensions in addition to its one-piece zinc die-cast housing.

The most important reasons:

• 1:1 conversion from IP20 to IP67 interfaces possible

• Saving of installation space

• Robust one-piece zinc die-cast housing

• different series available (ST, HD, Combination)

CONEC IP67 Fiber Optic LC Duplex Connectors

CONEC IP67 Fiber Optic LC Duplex connectors offer secure and fastest option for data transmission. Suitable for industry with standard LC interfaces according to IEC 61754-20. Protection class IP67/IP68 Available as Single Mode (SM), Multi Mode (MM) and APC Single Mode (APC-SM).

CONEC IP67 Power Bayonet Series

The connector series is designed for industrial cable connections with IP67 protection and the bayonet locking allows a quick, simple, and robust connection in harsh environments. The 2-pos. version is mainly designed for DC use up to max. 48 V DC and the 3-pos. version utilizes a premating contact for AC up to max. 250 V AC with protective earth contact (PE).

CONEC IP67 RJ45 series Cat5e & Cat6A

The connector series is designed for Industrial Ethernet wiring with protection degree IP67 and the bayonet locking allows fast, simple and robust connection in harsh environments. The broad portfolio includes connectors in plastic, metalized plastic or full metal.

CONEC IP67 USB series

Data communication is also required in outdoor applications. Whether in traffic engineering, in maritime environments or mobile phone applications, long transmission distances and impacts such as heat, rain, snow, salty mist and dust place high demands on all connectors. The IP67 USB connectors developed by CONEC provide reliable protection against environmental influences and mechanical stress.

CONEC ISOBUS Series

With increasing demands on efficiency in agriculture, precision farming is becoming more and more important. Precision farming is the targeted management of utilized agricultural land.

To ensure the necessary communication between tractors, equipment, and agricultural management software, the non-proprietary ISOBUS is used.

CONEC M12x1 Series L-Coding

The overmoulded M12 L-coded connectors require 30% less installation space compared to a 7/8″ connector. Due to the high current carrying capacity of 16 A with a strand cross-section of 2.5 mm², they are also able to ensure the power supply of devices via a miniaturised interface. Also available: sockets & field attachable connectors.

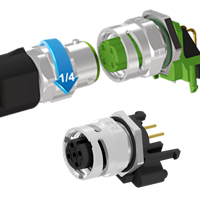

CONEC M12x1 Series with Bayonet Quick Locking

The CONEC connector series with bayonet quick locking system allows safe and quick locking even in areas that are difficult to reach and/or not visible. With the “three-point” bayonet locking it is possible to lock the connection by hand with a 90 ° turn. You get direct tactile and acoustic feedback as soon as the connector is locked.

CONEC M12x1 Series X-Coding

In view of the increasing amount of data in industrial plants, designers and planners are faced with the question of how to transfer data quickly and reliably. Typical areas of application that require continuously higher data transmission rates are, for example, vision and scanner systems for production monitoring and real-time data evaluation.

CONEC Series M8x1 D-Coded "Fast Ethernet"

With M8x1 D coding, Industrial Ethernet transmission is implemented using a 4-pole M8x1 connector in conjunction with a 360° shielding and a standard Ethernet cable. Together with the contacts changed to 0.8 mm diameter, the connector enables a transmission rate of up to 100 Mbit/s (Fast Ethernet).

CONEC Series M8x1 P-Coded "EtherCAT P"

The special feature of EtherCAT-P is the combination of superfast EtherCAT communication with the 24 V power supply. Data and power (Us) for system and sensor supply with 24 V and 3 A are provided on a two-wire data pair. The second data pair provides data and the peripheral voltage (Up) for the supply of the actuators.

CONEC SnapLock D-Sub Hoods & Connectors

You are searching for a D-SUB hood system that enables quick and easy locking and unlocking without additional tools? That allows a locking even at poorly visible device interfaces due to the audible and tangible ” click”? Do you want to upgrade an existing system with quick-release Hoods? The new CONEC SnapLock locking system consists of D-SUB connectors and D-SUB hoods allowing quick locking.

Connectors for Electric Vehicles

Discover our variety of high voltage connectors for electric vehicles. Each has a safety interlock system and is waterproof. Our experience for all kinds of products in High Voltage and High Current applications, is a driver for a sustainable future with more green propulsion systems. We are regularly expanding our HV portfolio to meet market trends or to develop specific solutions for customers.

Connectors with Cable

M8 actuator sensor cables, motor, feedback, and hybrid cables. M12 actuator sensor cables (3–8 pole, A-coded). M12 network cables (B-, D-, X-coded) for Ethernet, Profinet, Sercos, and EtherCAT. RJ45 network cables also available.

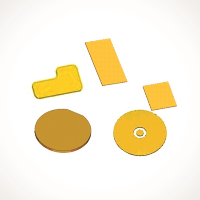

Contact Pads

Amphenol's contact pads are used in contact areas and as spacers on PCBs. Durable plating includes a diffusion barrier. The contact pads connect with low resistance over the product's lifetime for use in sensitive connections of antennas, microphones, and carbon PCBs. They are available in a wide variety of shapes and sizes. Thickness: scalable ≥ 0.1 mm.