Connectors

Amphenol has been designing and manufacturing electrical and electronic connectors since the company’s inception in 1932. For nearly a century, we’ve been helping customers transmit power, data and signal in the harshest environments, from subsea applications to the outer reaches of space and everywhere in between. Our wide array of electrical and electronic connectors come in multiple form factors and are designed to meet the latest market needs including high power, high speeds, size and weight reduction, EMI shielding, hermeticity, high pressure and improved board retention. Amphenol also offers a broad portfolio of contact styles, termination types, mating styles, connector geometries and environmentally-friendly RoHS plating.

View our businesses providing Connector solutions.

Magnetic Jack (RJMG) - 2xN

RJMG series offers a wide variety of fully RoHS compliant Magnetic Modular Jacks for RJ45. The right angle and through-hole type are offered in 2xN (2x1, 2x2, 2x4, 2x6, and 2x8) port with tab-up and tab-down options. This series comes with LED options and is compatible with Power over Ethernet (PoE). RJMG series is offered with both shielded and EMI options, which provides enhanced protection.

Magnetic Jack (RJMG) - Stacked

RJMG series offers a wide variety of fully RoHS compliant Magnetic Modular Jacks for RJ45. The right angle through hole type is offered in RJMG Stacked USB 2.0/3.0. This series comes with LED options and is compatible with Power over Ethernet. RJMG series is offered with both shielded and EMI options, which provides enhanced protection. Gold plating option is also available for the contact area.

Magneto-Lok Connector

Amphenol LTW's Magneto-Lok series offers a low-profile, self-aligning magnetic connection with 360°rotation and quick disconnect at any angle. Available in both receptacle and overmolded versions. With insulation resistance of 100 MΩ, voltage ratings up to 12Vdc / 24Vdc, and a vibration resistance 10 ~ 55 Hz, it ensures reliable performance for up to 10,000 mating cycles.

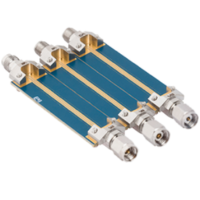

Male Solderless PCB Connectors

SV Microwave’s high speed RF/coaxial solderless male edge launch and compression mount connectors are ideal for high frequency PCB applications where precision is key. These rugged, durable and reuseable connectors accommodate multiple PCB thicknesses and do not cause damage to the printed circuit board. Current interface configurations include high frequency SMA, 2.92mm, 2.4mm and 1.85mm series.

Manual Service Disconnect (MSD)

MSD: Manual Service Disconnect, with safe, reliable solutions for servicing high voltage systems. it utilizes a two-stage lever to open the HVIL circuit prior to separation of high voltage contacts. This tool-free solution for disconnecting the internal HV battery pack and protecting the battery pack HV cables from short-circuiting is available in a scalable design with a variety of fuse ratings.

Martec AlloyBronze

Engineered to withstand the demands of marine environments, this material can be specified on many of our popular products for use in Naval and Marine applications

Key Features

Excellent salt corrosion resistance

Ideal for marine environments

High Strength-to-weight ratio

High conductivity and resistance to sparking

Fluid compatibility : highly chemical resistance

Martec Julus

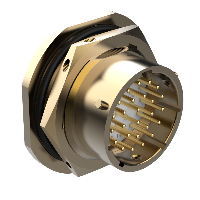

Martec presents the Julus Range, a collection of high-performance hermetic connectors designed and manufactured exclusively for demanding applications where integrity is crucial.

Our Julus industrial feedthrough connectors bring reliability and performance to electronic systems throughout the military, aerospace and industrial sectors.

Martec Nimbus

Martec presents the Nimbus range – a series of lightweight high-performance hermetic connectors designed and manufactured exclusively for demanding applications where integrity is crucial.

Our Nimbus aluminium connectors bring reliability and performance to electronic systems throughout the Aerospace, Military, Space and Motorsport industries.

Martec Phoenix

Martec presents the Phoenix Range, a series of high-performance hermetic connectors. Our connectors are designed and manufactured exclusively to meet the demanding environmental needs of applications requiring elevated temperature performance compared to COTS connectors.

Max-M12

This series, a high-speed SAE J2839 compliant, ruggedized harsh environment, metal threaded coupling signal connector. With over 10 insert arrangements ranging from 3 to 12 contacts per connector and up to 16 amps possible with a standard operating temperature from -40°C to +85°C.

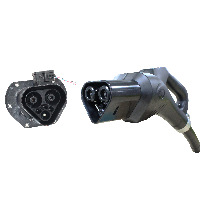

MCMSD

MCMSD is an Electric Vehicle-friendly connector that has been mainly designed for Energy Storage.

M-CRPS +54V Connectors & Cable Assemblies

Amphenol's M-CRPS (+54V) Connectors and Cable Assemblies are designed to meet the Open Compute Project's M-CRPS power supply input specifications, providing robust performance and flexibility. Capable of delivering up to 40A per contact, these connectors support 8AWG - 12AWG wire sizes, enabling standardized DC-MHS rack and power architecture while maintaining design adaptability.

MCS

Megawatt Charging System, with vehicle

charging connector and cooling system, for charging electricvehicles(EV) with direct current(DC), MCS compliant with :IEC 61851-23-3, IEC TS 63379. Raated current for plug 350A &1500A, for inlet 1000A & 3000A. Rated volatge 1500V.

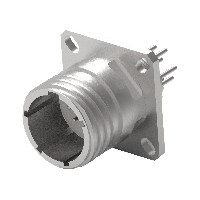

MCX Connector Series

The MCX (Micro Coaxial) series is a 50 Ω series with broadband capability ranging from DC to 6 GHz. In addition, the MCX series features secure, fast and easy snap-on/ snap-off coupling.

MDP FTV

Amphenol SOCAPEX rugged Display solutions are designed to transmit video data & information in harsh environments for applications such a C5ISR, ground vehicles, navy. It ensures a reliable transmission between display screens, cameras, computers. Any standard Displayport plug or cordset is converted into a military-grade solution for harsh environments with high level of sealing and durability.

MDP FTV

MDP Field is Mini DisplayPort interconnect system for harsh environments. MDP FTV is a complete ruggedized solution around Mini DisplayPort to allow you to insert a standard Mini DP cordset into a metallic plug which will protect it from shocks, dust and fluids.

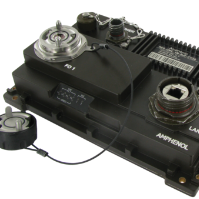

Media Converter RES-GMC-1M-FORC with Fiber Remote control

Amphenol’s RES-GMC-1M-FORC is a MIL-STD rugged, unmanaged-military-grade Media converter, offering Gigabit communication. Developed for network deployment in harsh environment applications, the RES-GMC-1M-FORC series serves as a robust solution to extend your Tactical Gigabit Ethernet network over fiber.

Media Converter RES-GMC - Expanded Beam Technology

Amphenol’s RES-GMC is a MIL-STD rugged, unmanaged-military-grade security gateway, offering up to 2 Gigabit security gateways per device for unidirectional and data diodes solution for total isolation between two networks with different security classifications. The unit supports PoE on 2 ports (IEEE802.3af and IEEE802.3at).

Media Converter RES-GMC-with Butt Joint Fiber Connector

Amphenol’s RES-GMC is a MIL-STD rugged, unmanaged-military-grade security gateway, offering up to 2 Gigabit security gateways per device for unidirectional and data diodes solution for total isolation between two networks with different security classifications. The unit supports PoE on 2 ports (IEEE802.3af and IEEE802.3at).

Media Converter RJS-BKN-2UG with Butt Joint Fiber Connector

With industrial EMI compliancy